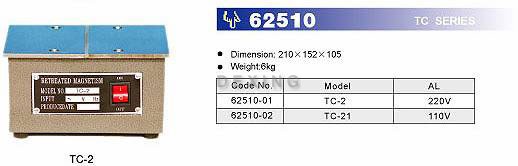

Portable Magnetizer & Demagnetizer

Protable magnetizer / Demagnetizer

Loop demagnetizer

CT series loop demagnetizers are durable devices based on prov-

en technology. The magnetic parts are drawn slowly (~0.15 m/s)

through the coil opening. The parts are demagnetized through

removal along he coil axis. The bigger the coil, the greater the

magnetic field limit. The material must completely pass outside

this field.

CT series loop demagnetizers are durable devices based on prov-

en technology. The magnetic parts are drawn slowly (~0.15 m/s)

through the coil opening. The parts are demagnetized through

removal along he coil axis. The bigger the coil, the greater the

magnetic field limit. The material must completely pass outside

this field.

These devices reliably demagnetize parts up to a thickness of

20 mm. When short parts are demagnetized, the penetration

depth of the field is less than 10 mm. Hard magnetic materials are

not demagnetized properly by these devices.

Characteristics of Loop demagnetizer

1. Sturdy,forshopflooruse

2. Versatile

3. Particularly suitable for easily alloyed and oblong parts

| Coilmodule | CT1 | CT2 | CT3 | CT4 | CT5 | CT6 | CT7 | CT8 |

| Dimensions W x H x D [mm]1 | 450x290 x150 |

560x320 x170 |

560x440 x190 |

700x390 x230 |

700x540 x230 |

700x590 x230 |

850x740 x350 |

1050x740 x350 |

| Active opening W x D | 150 x 100 mm | 260 x 130 mm | 250 x 250 mm | 400 x 200 mm | 400 x 350 mm | 400 x 400 mm | 550 x 550 mm | 750 x 550 mm |

| Maximum field, peak 2 | 25 kA/m | 29 kA/m | 20 kA/m | 26 kA/m | 18 kA/m | 17 kA/m | 11 kA/m | 9 kA/m |

| Magnetic field limit3 | 500 mm | 780 mm | 1000 mm | 1200 mm | 1500 mm | 1600 mm | 2200 mm | 2600 mm |

| Duty cycle | S1, 100 %, continuous operation | S1, 100 %, continuous operation | S1, 100 %, continuous operation | S1, 100 %, continuous operation | S1, 100 %, continuous operation | S1, 100 %, continuous operation | S1, 100 %, continuous operation | S1, 100 %, continuous operation |

| Weight | 41 kg | 62 kg | 84 kg | 110 kg | 120 kg | 130 kg | 190 kg | 230 kg |

| Connection | 230 VAC 50 / 60 Hz 4.5 A |

230 VAC 50 / 60 Hz 12 A |

230 VAC 50 / 60 Hz 15 A |

230 VAC 60 Hz 22 A |

230 VAC 50 / 60 Hz 30.5 A |

230 VAC 50 / 60 Hz 31 A |

230 VAC 50 / 60 Hz 30 A |

400 VAC 50 / 60 Hz 25 A |

| Protection class IP | 54 | 54 | 54 | 54 | 54 | 54 | 54 | 54 |

| Configuration | threaded | threaded | threaded | threaded | threaded | threaded | threaded | threaded |

2. Divide by 1,41 to obtain RMS value

3. Minimal distance for the removal of the part along the coil axis