Sintered AlNiCo magnets

|

|

Character of Sintered AlNiCo magnets

- Compact crystal, high intensity, good chemistry Stability, strong anti-corrosion.

- Even elements, excellent and stable magnetic performance;

- Excellent temperature stability (temp. coefficient of Br is the smallest among all of the other permanent magnets.)

- Highest usage temperature reach 500ˇć

- uitable for small volume and complex shape and magnet assemble for sintered Alnico.

Application of Sintered AlNiCo magnets

- Inner magnetic voltmeter/ammeter, electronic type power energy measuring instrument, avometer, flow meter;

- wide range of magnetic sensor, polarized relay, temperature and pressure controller;

- Buzzer of Mobile phone, hearing aids, mini speaker;

- Lighter of automobile, odometer of automobile and motorcycle, permanent motor, adsorptive appliance;

- idely applied in high stability fields as aviation and military technology.

Magnetic properties and physical characteristics

of sintered AINiCo permanent magnets

| Grade | (BH)max KJ/m3 |

Br mT |

Hcb kA/m |

Hcj kA/m |

d g/cm3 |

¦Á(Br) %/K |

Tc ˇć |

Remarks |

| ALNiCo4/1 | 3.2-4.8 | 870-890 | 9-11 | 10-12 | 6.8 | -0.02 | 750 | isotropy |

| ALNiCo8/5 | 8.5-9.5 | 530-620 | 45-50 | 47-52 | 6.8 | -0.02 | 750 | |

| ALNiCo10/5 | 9.5-11 | 630-700 | 48-56 | 50-58 | 6.8 | -0.02 | 780 | |

| ALNiCo12/5 | 11-13 | 700-750 | 50-56 | 53-58 | 7.0 | -0.02 | 800 | |

| ALNiCo14/5 | 13-15 | 730-800 | 47-50 | 50-53 | 7.1 | -0.02 | 790 | |

| ALNiCo14/6 | 14-16 | 620-810 | 56-64 | 58-66 | 7.1 | -0.02 | 790 | |

| ALNiCo14/8 | 14-16 | 550-610 | 75-88 | 80-92 | 7.1 | -0.01 | 850 | |

| ALNiCo18/10 | 16-19 | 570-620 | 92-100 | 99-107 | 7.2 | -0.01 | 860 | |

| ALNiCo35/5 | 35-39 | 1100-1200 | 48-52 | 50-54 | 7.20 | -0.02 | 850 | Anisotropy |

| ALNiCo29/6 | 29-33 | 970-1090 | 58-64 | 60-66 | 7.20 | -0.02 | 860 | |

| ALNiCo32/10 | 33-38 | 770-870 | 90-104 | 94-109 | 7.20 | -0.01 | 860 | |

| ALNiCo33/11 | 33-38 | 700-800 | 107-115 | 111-119 | 7.20 | -0.01 | 860 | |

| ALNiCo39/12 | 39-43 | 830-900 | 115-123 | 119-127 | 7.25 | -0.01 | 860 | |

| ALNiCo44/12 | 44-48 | 900-950 | 119-127 | 124-132 | 7.25 | -0.01 | 860 | |

| ALNiCo37/15 | 37-41 | 700-800 | 143-151 | 150-158 | 7.10 | -0.1 | 870 |

|

|

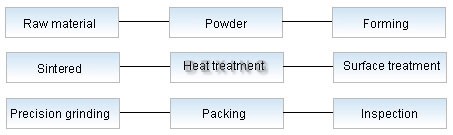

Process of sintered AlNiCo magnets