NdFeB Magnets

Products: sintered NdFeB magnets

Neodymium-iron-boron, Composition: Nd2Fe14B

is a permanent magnetic material with metallic composite of Nd2Fe14B as the base. Compared with the casting of Al-Ni-Co permanent magnetic materials and permanent magnetic ferrite£¬neodymium-iron-boron has stronger coercive force and £¨BH£©max£¬which can attract heavy objects weighing 640 times its weight. Its merit of higher energy density results in its widely application in modern industry and electronic technology, which makes the small size, light weight and thin set of instruments, audio and engines, magnetic separation and magnetizing equipment a possibility.

These alloys have a com-position of two rare earth atoms to 14 iron atoms with one boron atom. There may be a substitution of other rare earth and/or minor additions of other elements. Known as third generation of Rare Earth magnets, Neodymium Iron Boron NdFeB magnets are the most powerful and advanced commercialized permanent magnet today. Since they are made from Neodymium, one of the most plentiful rare earth elements, and inexpensive iron, NdFeB magnets offer the best value in cost and performance.

Characters of NdFeB:

The merits of neodymium-iron-boron is its excellent performance and cost ratio and good machinery feature of easy machining. Its demerits lie in its low curie temperature, bad thermal feature, easy erosion, which should be improved to achieve desired requirement with the adjustment of chemical composition and surface treatment.

Production process:

The production of neodymium-iron-boron adopts the powder metallurgical process to melt raw materials like Nd, Dy, iron, cobalt, niobium, praseodymium, aluminum, metallic boron and so on at a certain ratio with medium frequency induction furnace and casts into alloy ingot. Then mill into 3¡«5¦Ìm powder and compact in a die in magnetic field. The green compacts are sintered and annealled in the vacuum furnace. The sintered blocks will become the required neodymium-iron-boron for customers after the process of grinding, drilling, cutting and so on. The process is as follows:

Application of NdFeB Magnets

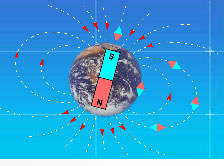

Offering the highest energy products ever available in production permanent magnet materials, NdFeB, namely Neodymium(Nd) -Iron(Fe)-Boron(B), the third generation of rare-earth permanent magnets and the strongest permanent magnets to date£¬widely used in apparatus and instruments where a strong magnetic field is needed such as devices for avionics, spacecraft, electronic instruments, electro-acoustic devices, electrical machinery, meters and medical instruments, high performance stepper, DC, servo, and linear motors, actuators, loudspeakers, headphones, instrumentation, switches, relays, magnetic imaging for medical and geophysical applications, holding systems, magnetic bearings, magnetic couplings, hard disk drives, etc.

This magnet is thus especially suitable for developing those new products demanding high quality, small volume and light weigh. NdFeB magnet can be used as an ideal magnet in mini-motor, permanent magnet instrument, electronic industry, auto industry, petro-chemical industry, nuclear magnetic resonance, sound device magnetic suspension system, magnetic transmission machine and iatrical apparatus and etc.

Lead-Times:

The prototypes is within 7 days while the delivery of small lot needs 10 days and large lot or special types needs 2-4 weeks (without ready die, it may take more 2-4 days). Stock magnets will be delivered within 24 hours. Just-in-time delivery as needed.

Special Service:

We are fully equipped to machine the magnets to your blueprint specifications. Customers are welcome to enquire.